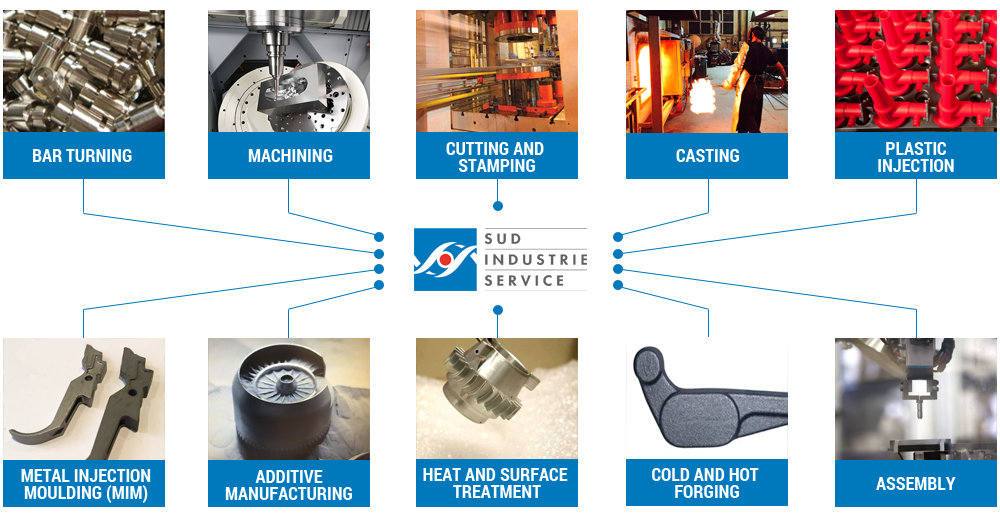

MANAGEMENT OF COMPLEX COMPONENTS:

MULTIPLE PROCESSES, MULTIPLE MATERIALS, MULTIPLE VOLUMES

> Over 5 million sub-assemblies produced every year <

OUR KEY EXPERTISE: ASSEMBLING AND WORKING MATERIALS

ASSEMBLY

Your partner for semi-automatic robotised welded, riveted or screwed assemblies

WORKING ON ANY MATERIAL

Your partner for the manufacture of your components in any material (steel, stainless steel, specific alloys, non-ferrous metals and plastics)

MULTIPLE INDUSTRIAL PROCESSES MASTERED BY OUR 65 SELECTED PARTNERS.

OUR CUSTOMERS HAVE ACCESS TO EVERY AVAILABLE MANUFACTURING TECHNIQUE THROUGH A SINGLE KEY CONTACT:

Activity:

Machining on lathes: single spindle, multi-spindle, CN, transfer machining. All finishing operations.

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals / Plastics

Dimension of parts:

∅ 1 to 200 mm

Up to 15kg

Tolerances:

Tolerance guaranteed up to +/-5µ in series

Option of +/-2µ in special manufacture with 100% control

Quantity:

From 1 to over 1 million parts

Activity:

Lathe and centrer machining

CNC machining into billets or bars

All finishing operations

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals / Plastics

Dimension of parts:

Ø 0.5 to 400 mm

Up to 15 kg

Tolerances:

+/- 2 µ

Quantity:

From 1 to 100 parts

Activity:

Wire, laser, water jet cutting

Standard cutting on presses 25 to 800T

Multiple slide cutting 25 to 45T

Fine blanking 40 to 250T

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals

Dimension of parts:

From 0.1 to 10 mm

6 mm in stainless materials

Max dimension 300 × 500 mm

Tolerances:

According to the process to be defined according to the needs

Quantity:

From 1 to over 1 million parts

Activity:

Sand casting

Gravity die casting

Pressure die casting

Atmospheric or vacuum lost-wax casting

Centrifugal casting

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals

Dimension of parts:

300x500mm max.

Up to 15kg

Tolerances:

Tolerance of casting or remachining up to +/- 10μ

Quantity:

From 1 to over 1 million parts

Activity:

25 to 1200T presses

Bi-material presses

Hydraulic presses

Electrical presses

Insert moulding

Materials:

PBT ABS PA6-6 PE PP PC PU Pa loaded FV

Dimension of parts:

300×500 mm max.

Up to 15kg

Tolerances:

Tolerance of plastic injection

Quantity:

From 100 to over 1 million parts

Activity:

Injection of a fine metal powder mixed with a binder. Principle similar to that of plastic injection and pressure casting, but results in much better mechanical properties

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals

Dimension of parts:

From 2 to 50 mm

Maximum length of 100 mm

Weight of 100 g max.

Tolerances:

Guaranteed tolerance below 3mm ± 0.05 – over 30 mm ± 0.25

The accuracy depends on the size and the definition of the component

Quantity:

From 20,000 to 1 million parts

Activity:

3D Direct Metal Laser Fusion (DMLS) reduces the manufacturing time of a complex part.

This technology is derived from rapid prototyping and is a competitive alternative to conventional manufacturing processes

Materials:

Aluminium / Stainless steels / Titanium / Inconels

Dimension of parts:

300x500mm max.

Max weight 15 kg.

Tolerances:

Standard tolerance ± 0.3% (lower limit ± 0.3 mm)

Quantité :

From 1 to 100 parts

Activity:

Any type of heat or surface treatment including special requests

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals

Dimension of parts:

300x500mm max.

Max weight 15 kg.

Tolerance:

According to tolerances of the plan to be refined, according to the standards of the different processes

Quantity:

From 1 to over 1 million parts

Activity:

Cold wire forging: up to 6 matrix.

Forge with drop hammer or pneumatic with a crank 700 tons

Hot forging: forging under hydraulic and crank press 700 tons

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals

Dimension of parts:

Cold heading: Ø 2 to 24mm

Forge: 10 g to 10 kg

Tolerances:

Tolerance of cold heading or forging or remachining up to +/- 10μ

Quantity:

From 1,000 to over 1 million parts

Activity:

MIG/TIG/TOP TIG welding

3KW Fiber laser welding

EB welding

Brazing

Riveting, screwing, bonding

Marking

Robotic, automated and manual processes

Materials:

Steels / Stainless steels / Super alloys / Non-ferrous metals / Plastics

Dimension of parts:

1000x400mm max.

Max weight 15 kg.

Tolerances:

Tolerance to be defined according to customer drawing

Quantity:

From 1 to over 1 million parts

HIGH ADDED VALUE TECHNICAL PARTS

FOR DEMANDING SECTORS

From a prototype to larger volumes, we have the solution for your projects, thanks to a vast and varied experience of the industrial sectors for complex and multi-technology functions

Automotive

Aerospace

Mechatronics

Medical

Railway industry

Professional equipment